Concrete Polishing

ABRASIVE CONCRETE POLISHING

ARCHITECTURAL CONCRETE SYSTEMS DESIGNED FOR EXISTING CONCRETE OR NEW CONSTRUCTION

Make the Complex Simple

Max Defense™

Green Umbrella® Max Defense™ system wins a high-performance architectural concrete floor with products designed to play well together. Created for owners and design professionals who have experienced the failure of products that do not team well. A system for the success of interior polished concrete @MatureAge™. Uses the GreenCut Abrasives™ system that includes the surface refinement cutting agent GreenCut®. Profile with a conventional grinder or a fitted finishing trowel to see unfair production rates compared to the competition. Process using selected GC abrasives—BigStock™, GC-X™, GC-Eraser™, and PolishPlus™—to create a superior mechanical foundation defense with any specified class of profile or gloss. The Max Defense system first covers the field with DryShield™, our highly abrasion-resistant flagship densifier that fills the concrete void. Shield & Enhance™ is next in the lineup to protect from salt with superior stain protection. Bring a fantastic finish with Interior Microfilm™, a repairable wear-guard that brings clarity to the profile. Max Defense promotes bonding and cross-linking within the concrete without the negative side-effect of ASR or topical delamination found with other products. Maintain with GreenClean™ as part of the LifeCycle™ Maintenance system. All of this is a “Concrete Floor’s Best Game Plan.”

Base Defense™

Green Umbrella® Base Defense™ system is a basic entry-level, complete system for interior architectural concrete floors to be abrasively processed @MatureAge™. Start with a wet process and the liquid surface refinement cutting agent GreenCut™. Profile with a conventional grinder or a fitted finishing trowel. Various GC abrasives—GC-BigStock™, GC-X™, GC-Eraser™, and GC-PolishPlus™—play ball with any specified class of profile or gloss. Base Defense first covers the field with DryShield™, our highly abrasion-resistant flagship densifier that fills the concrete voids. Get a home run finish with the repairable wear-guard, Interior Microfilm™, bringing clarity to the profile. Base Defense promotes bonding and cross-linking within the concrete without the negative side-effect of ASR or topical delamination. Finally, use GreenClean™—part of the LifeCycle™ Maintenance system—to create a daily defense for the floor. All of this to cover your bases.

ColorFusion Defense™

Green Umbrella® ColorFusion Defense™ system fuses a cut with one abrasive with color, densifier, and wear-guard. The substrate is prepared using a simplified abrasive profile or honing process. Next, a UV stable color hardener—ColorShield™—is introduced and built up from the near subsurface, creating a uniquely durable, natural, or colored concrete surface. A single GC-Fusion™ abrasive cut combined with ColorShield produces a unique, soft color blended appearance. The ColorFusion system presents a value-engineered option to achieve an architectural concrete floor with a fully abrasively processed floor in a fraction of time. Use in varied environments with high moisture (challenging the success of traditional salt dyes) or UV exposure, interior and exterior applications, leaving you to choose ColorBox™ or NanoDye™ as your color base, mixed before application. Colorfast, hardened, chemically resistant, easy to apply, repairable. ColorFusion Defense creates the best of both worlds—profiled and sealed architectural concrete—using environmentally-friendly, low VOC solutions that have simplified the colored concrete landscape.

ABRASIVE POLISHING OF NEW CONCRETE @EarlyAge

GREENICE CURE

GreenIce Cure™ provides a cure and finish for concrete that stops moisture-related deterioration and other moisture problems. Concrete failures due to salt, chemical penetration, moisture penetration, and freeze-thaw cycles cause most of the concrete deterioration in the country. The GreenIce Cure system is designed to cure concrete faster, increase abrasion resistance, and add a high-gloss finish!

CANVAS CONTROL

Green Umbrella® Canvas Control™ is a system for interior or exterior applications. Installed @EarlyAge™ using components that cure, color, eliminate control joints and concrete shrinkage, and reduce curl. Using this system, product usage is reduced to six from conventional concrete placement methods that would require twice the amount of products.

ABRASIVE POLISHING OF EXISTING CONCRETE @MatureAge

BASE DEFENSE

The Green Umbrella® Base Defense™ system includes products that complement one another. DryShield™ increases hardness while reducing porosity in polished concrete floors. Interior MicroFilm™ is an environmentally friendly hybrid surface treatment that creates a durable micro-thin layer to seal polished concrete.

- Requires no rinsing and disposal and

- Won’t not gel on the surface and can be allowed to air dry

- Stands up to heavy abrasion and foot traffic while providing excellent slip resistance

- PH neutral and won’t interfere with the application of concrete dyes

- Decreases black tire marking from lift trucks and other equipment

MAX DEFENSE

Concrete treatments that complement one another and a properly profiled, honed, and polished floor can create a winning combination for your polished concrete needs. Max Defense™ includes:

- Dry Shield™ has one of the highest abrasion resistance levels on the market

- Green Umbrella Shield & Enhance™ has a superior chloride screen

- Interior MicroFilm™ offers a repairable surface layer

COLOR DEFENSE

Coupled with the proper mechanically profiled, honed, and polished floor, complimentary products can create a winning combination for your polished concrete floor. The Color Defense system includes the following:

- Dry Shield™ has one of the highest abrasion resistance levels on the market

- Shield & Enhance™ has a superior chloride screen

- Interior MicroFilm™ offers a repairable surface layer

- NanoDye™colorant for a deep penetrating color that won’t fade

COLORFUSION DEFENSE

The Green Umbrella® ColorFusion Defense™ system fuses a cut with one abrasive with color, densifier, and wear-guard. It creates the best of both worlds—profiled and sealed architectural concrete that uses environmentally friendly and low VOC solutions that have simplified the colored concrete landscape. Its benefits include:

- Quick installation

- UV stable color

- It can be used both inside and outside without fading

- No need for sealers, paints, or epoxies that flake off

- Increases hardness and density while

- reducing porosity

- Not a stain

- No harmful or toxic chemical polishing

PROJECT SUPPORT

PROJECT CONSULTATION

Construction is complicated, and so is concrete. Let us help you by making the complex simple. Consult with our team on any facet during any construction phase, from introducing fiber to color to shrinkage compensating components into the mix to integrally troweled cures. We love concrete, and we are happy to help.

Call, e-mail, or chat with us today.

SYSTEMS SPECIFICATIONS

Why Specify a System?

Successful teams are cohesive, play well together, overcome adversity, and present a consistent product every time.

Green Umbrella’s treatment systems do just that—produce consistent results using a family of treatments that have many features and benefits, such as being pH neutral, 100% reactive, and low or zero VOC.

GREEN UMBRELLA CERTIFIED

To meet the need to find contractors who can be relied upon to meet specifications consistently, Green Umbrella® has been instructing and training contractors in the Green Umbrella mechanical process and treatment applications that create an architectural concrete floor.

When contractors complete our comprehensive training program, we can confidently refer them to you.

Green Umbrella Certification Levels

Green Umbrella has three different levels of certification offered to meet your needs. The Green Umbrella Applicator, the Green Umbrella Craftsman, and the Green Umbrella Master Craftsman are trained at different levels and certified to use our concrete treatments for an earth-friendly concrete floor. Finally, we offer Green Umbrella Approved Producers.

Equipment, Abrasives, and Treatments

All Green Umbrella® polished concrete systems require the coupling of mechanical processes with various treatment options. Profiling, honing, and polishing are best achieved using a wet process performed using a propane concrete grinder with the correct abrasive tool.

Green Umbrella educates, trains, and equips all craftsmen to be certified to craft quality on-site.

Why Are We Systems Based?

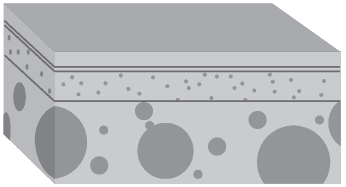

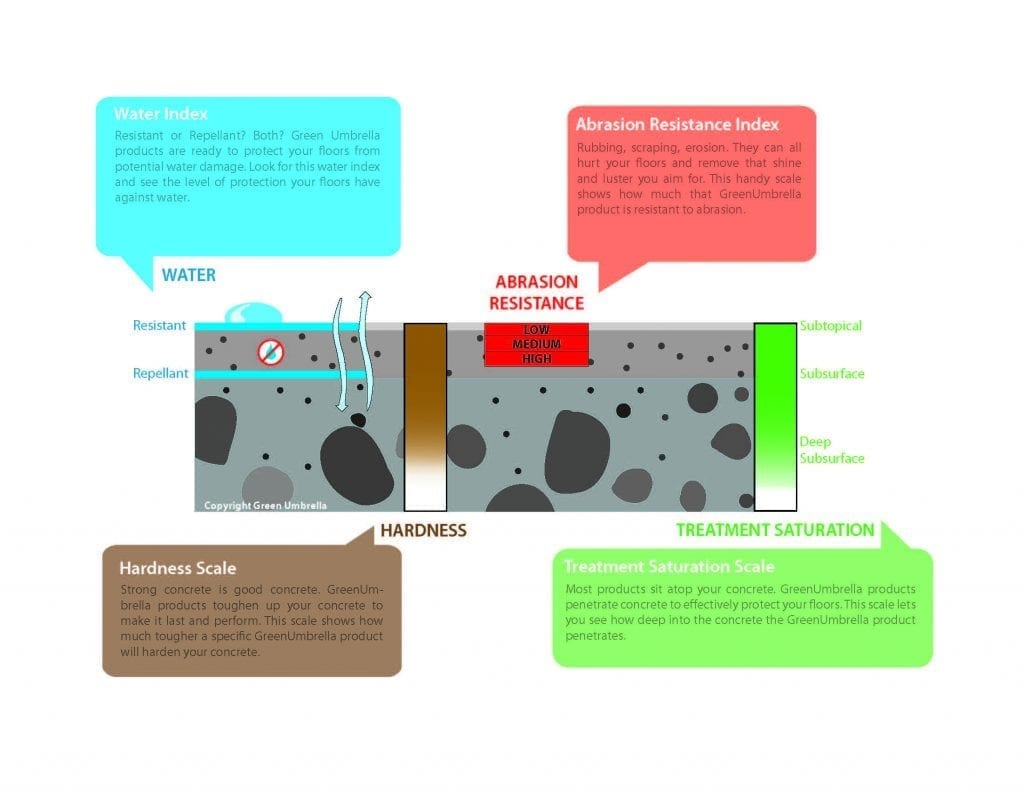

Treating concrete is not simply a matter of addressing a visible surface. Lasting concrete refinement addresses the wear surface and penetrates to subtopical, even deep subsurface, realms of the architectural concrete.

Implementing a family of concrete treatments ensures that the cutting agent, densifier, chloride screen, color, acid blocker, and other contaminant-resistant and microfilm-forming treatments all work together.

Message Us

Get in touch below and register to learn more about concrete polishing.

CALL US AT (844) 200-7336

OFFICE LOCATION

20 Jetview Drive

Rochester, NY 14624

OPEN HOURS

M-F: 9am – 5pm

info@greenumbrellasystems.com