Max Defense System

Product Download

System CutSheet

System Value Brochure

System Application Pac

System Technical Data Sheet Pac

System Safety Data Sheet Pac

Specification Download

CONCRETE FLOOR’S BEST GAME PLAN

Green Umbrella® Max Defense™ system wins a high-performance architectural concrete floor with products designed to play well together. Created for owners and design professionals who have experienced the failure of products that do not team well. A system for the success of interior polished concrete @MatureAge™. Uses the GreenCut Abrasives™ system that includes the surface refinement cutting agent GreenCut®. Profile with a conventional grinder or a fitted finishing trowel to see unfair production rates compared to the competition. Process using selected GC abrasives—BigStock™, GC-X™, Fusion™, Eraser™, and PolishPlus™—to create a superior mechanical foundation defense with any specified class of profile or gloss. The Max Defense system first covers the field with DryShield™, our highly abrasion-resistant flagship densifier that fills the concrete void. Shield & Enhance™ is next in the lineup to protect from salt with superior stain protection. Bring a fantastic finish with Interior Microfilm™, a repairable wear-guard that brings clarity to the profile. Max Defense promotes bonding and cross-linking within the concrete without the negative side-effect of ASR or topical delamination found with other products. Maintain with GreenClean™ as part of the LifeCycle™ Maintenance system. All of this is “Concrete Floor’s Best Game Plan.”

PROCESS, EQUIPMENT, & ABRASIVES

Green Umbrella equipment and abrasives are designed specifically for wet profiling. Equipped with a standard quick change system to promote even abrasive wear and quick field changes, cutting downtime on PHP projects.

The wet process eliminates airborne crystalline silica dust and its potential health hazards, such as silicosis due to inhaling these dangerous airborne particulates, and improves indoor air quality. Propane is one of the cleanest burning fossil fuels, cutting emissions and leaving a smaller carbon footprint than a typical electric model.

GreenCut® starts by creating a slurry that produces a denser surface, reducing seven abrasive cuts to as few as two.

GC-BigStock™ abrasives can be used for increased aggregate exposure. Ideal for architectural concrete featuring a large aggregate reveal. Optional

GC-X™ abrasives are powerful 10-segment metal abrasives designed for use with Green Umbrella® GreenCut®. Optional

GC-Fusion™ abrasives are a hybrid bond of industry-leading metals and resin. Four different abrasive grits are available to achieve the desired RA (roughness average) on the slab.

The GC-Eraser™ class of semi-metal honing abrasives is engineered for specific surface refinement.

Designed for use within Green Umbrella® Base Defense™, Max Defense™, and other profile systems, our GC-PolishPlus™ abrasives finish off the process to achieve the desired surface sheen.

GreenUmbrella® NanoDye™ concrete colorant is an interior, translucent, subsurface, pH-neutral dye that utilizes nano-sized particulates to penetrate the concrete, depositing colorant into the concrete subsurface and promoting a longer lifecycle.

Shield & Enhance™ is an environmentally formulated premium hardener. Shield & Enhance is engineered as a color-guard to enhance colored and profiled architectural concrete floors, providing a darker, clarified-gloss appearance. As a unique oxidation inhibitor, Shield & Enhance significantly increases a salt pigmented or nano dye’s lifecycle, extending colorfastness.

Interior MicroFilm™ is an R.T.U. repairable impregnating micro-treatment for abrasively profiled architectural concrete floors.

SUPERIOR PERFORMANCE, MECHANICALLY PROFILED

PREVENTS CONCRETE OFF-DUSTING

HYDRAULIC FLUID, SALT, & STAIN RESISTANT

HIGHLY ABRASION-RESISTANT

WATER-RESISTANT WITH WEAR-GUARD

Features & Benefits

- Designed for environmental wet profiling, honing, and polishing

- pH neutral

- Will not form white residue that has to be re-cut

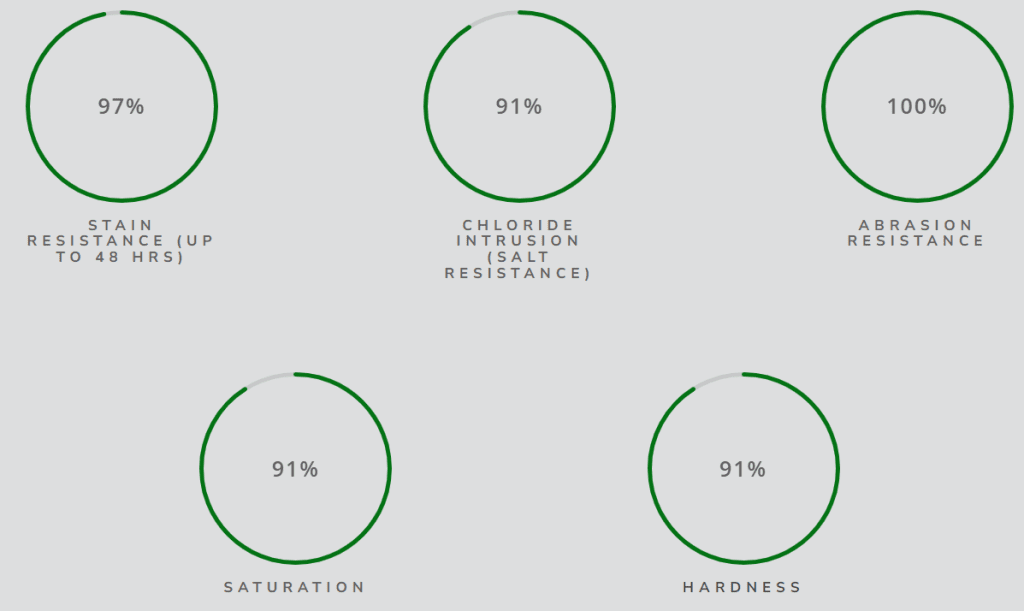

- Increases hardness and density while reducing porosity

- Requires no rinsing and disposal and will not gel on surface

- Resists penetration by oils, chemicals, and other stain-causing materials

- Decreases black tire marking from lift trucks and other equipment

- Increased hardness and density

- Adds dust- and stain-proofing properties

- Salt Protectant

- Excellent resistance to efflorescence, fungi, and mildew growth

- Stands up to heavy abrasion and floor traffic while providing excellent slip resistance

- Highly resistant to aviation oils for up to 48 hours

- Resists acid and chemical exposure

- Not prone to whitening

- Will not peel or flake

- USDA/FDA approved for incidental food contact

- Very low maintenance

- Does NOT contribute to ASR (alkali-silica reaction)

Cut Your Labor

- Achieve the properties of a polished concrete floor during the normal pour and finish with no additional labor

Cut Your Downtime

- A system installed in days instead of weeks or weeks instead of months

- Process and complete a polished floor without holding up a project

Cut Your Environmental Impact

- Environmentally friendly treatments

- Water and silica-based

- Reduces construction waste because treatment is incorporated into the slab

MAKING THE COMPLEX SIMPLE

GREEN UMBRELLA DEFENSE SYSTEMS

MESSAGE US

Get in touch to find out what Base Defense can do for your next concrete project.

CALL US AT (844) 200-7336

OFFICE LOCATION

20 Jetview Drive

Rochester, NY 14624

OPEN HOURS

M-F: 9am – 5pm

info@greenumbrellasystems.com