GreenIce Concrete Cure & Profile

Product Downloads

System Cut Sheet

System Value Brochure

System Application Pac

System Technical Data Sheet Pac

System Safety Data Sheet Pac

Specification Downloads

CutSpec: Short Specification

CSI Specification with Designer Notes

Make Your Concrete Dance

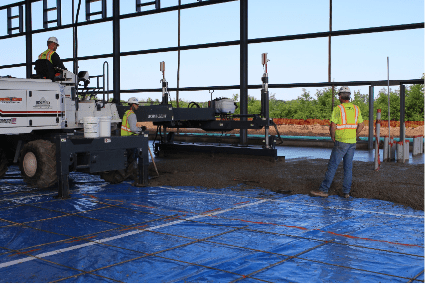

Green Umbrella® GreenIce Cure & Profile™ system is primarily an interior @EarlyAge™ integral concrete cure. It starts with the use of IceStart™ concrete cure during finishing. Once finished, the fixative IceStop™ is applied. GreenIce Cure™ creates a highly consolidated and refined surface that is the basis for an unconventional floor and promotes the best concrete practices, improving edges and FF/FL numbers. With GreenCut™, a unique liquid abrasive cutting agent, and various GC abrasives—GC-BigStock™, GC-X™, GC-Fusion™, GC-Eraser™, and GC-PolishPlus™—cover any class of profile, including an unconventional, highly-reflective polish. Advancing construction staging allows mechanical profile, hone, and polish to be performed days after placement—not months—using a conventional grinder or a fitted finishing trowel. Combines the profile system Max Defense™, the densifier DryShield™, the salt protection Shield & Enhance™, and the repairable wear-guard Interior Microfilm™ to provide the ultimate hardness, density, abrasion resistance, and stain resistance in the industry while retaining the maximum moisture within the concrete during curing for an unconventional architectural concrete floor that is performance ready.

HIGH-PERFORMANCE POLISHED CONCRETE GREENICE CURE

PROMOTING BEST CONCRETE PRACTICES

CURE AND DENSIFICATION BENEFITS @DayOfPlacement™

CONSTRUCTION STAGING @EarlyAge™

PLACEMENT IMPERFECTIONS REMOVED

OPTIONAL CLASS OF MECHANICAL PROFILE

OPTIONAL UNCONVENTIONAL POLISHED GLASS APPEARANCE

The GreenIce Polished Concrete Cure System

The GreenIce Cure™ system is a two-part patent-protected concrete curing solution designed to cure polished concrete faster, increase abrasion resistance, and add a slip-resistant, high-gloss finish that looks like ice!

IceStart™ is a unique concrete curing agent used to ensure an adequately cured floor and is the first of the two-part GreenIce Cure™ system. It uses a treatment and trowel process to achieve high-performance floors.

IceStop™ is the second part of the GreenIce Cure™ system. IceStop is applied after IceStart™ to create a protected and properly cured concrete slab.

After the floor is properly cured, IceStop™ increases the strength and longevity of the slab. Stop here or top it off with IceCap™ to add a beautiful high-gloss finish and achieve peak protection.

GreenCut® starts by creating a slurry that produces a denser surface, reducing seven abrasive cuts to as few as two.

GC-BigStock™ abrasives can be used for increased aggregate exposure. Ideal for architectural concrete featuring a large aggregate reveal. Optional

GC-X™ abrasives are powerful 10-segment metal abrasives designed for use with Green Umbrella® GreenCut®. Optional

GC-Fusion™ abrasives are a hybrid bond of industry-leading metals and resin. Four different abrasive grits are available to achieve the desired RA (roughness average) on the slab.

The GC-Eraser™ class of semi-metal honing abrasives is engineered for specific surface refinement.

Designed for use within Green Umbrella® Base Defense™, Max Defense™, and other profile systems, our GC-PolishPlus™ abrasives finish off the process to achieve the desired surface sheen.

GreenUmbrella® NanoDye™ concrete colorant is an interior, translucent, subsurface, pH-neutral dye that utilizes nano-sized particulates to penetrate the concrete, depositing colorant into the concrete subsurface and promoting a longer lifecycle.

Shield & Enhance™ is an environmentally formulated premium hardener. Shield & Enhance is engineered as a color-guard to enhance colored and profiled architectural concrete floors, providing a darker, clarified-gloss appearance. As a unique oxidation inhibitor, Shield & Enhance significantly increases a salt pigmented or nano dye’s lifecycle, extending colorfastness.

Learn More

Interior MicroFilm™ is an R.T.U. repairable impregnating micro-treatment for abrasively profiled architectural concrete floors.

Cut Your Environmental Impact

Concrete canvas systems use fewer products to achieve a superior result.

Product Reduction

4-5

GreenIce

Cure & Profile

7-10

Conventional Slab

| Conventional Product | GreenIce Cure | GreenIce Cure & Cap | GreenIce Cure & Profile | Product to Specify |

|---|---|---|---|---|

| Products to Support Water Cure | Not Required | Not Required | Not Required | |

| Finishing Aid | x | x | x | IceStart / IceStop |

| Shake-On Hardener | x | x | x | IceStart / IceStop |

| Cure & Seal | x | x | x | IceStart / IceStop |

| Liquid Densifier | x | x | x | IceStart / IceStop |

| Liquid Hardener / Dust-Proofer | x | x | x | IceStart / IceStop |

| Sealer & Stain Protectant | x | x | IceCap or Interior MicroFilm | |

| Surface Imperfections Reduced (4 Abrasives) | x | x | 1-2 GreenCut Abrasives | |

| Aggregate Exposure (5-6 Abrasives) | Choose | Choose | 2-3 GreenCut Abrasives | |

| Unconventional High Gloss Appearance | Optional | Optional | 2-3 GreenCut Abrasives | |

Features and Benefits

High-Performance Concrete

- Ease of finishing, eliminates false set

- Reduces drag on the concrete, meets slip resistance standards

- Reduces subsurface lateral microcracking

- Removes cat faces

- Extends workability in hot weather

- Does not extend set times in cold weather

- Allows finishing of dry shake as if it is normal concrete

- Looks like a mechanically polished (PHP) floor

- Better protection than found on mechanically finished floors

- Opens new markets for flatwork contractors

Cut Your Labor

- Achieve the properties of a polished concrete floor during the normal pour and finish with no additional labor

Cut Your Downtime

- A system installed in days instead of weeks or weeks instead of months

- Process and complete a polished floor without holding up a project

Cut Your Environmental Impact

- Environmentally friendly treatments

- Water and silica-based

- Reduces construction waste because treatment is incorporated into the slab

Making the Complex Simple

GET AN EDITABLE SPEC FOR YOUR PROJECT

Request a Project Spec Today! Or Call (844) 200-7336