GreenXtreme

Unparalleled / Profile&Polish / Productive

Product Download

GreenXtreme Technical Data Sheet

GreenXtreme Parts Manual (Email Us to Request)

Propane Safety Awareness

Silica SDS Sheet

Equipment Lease

Equipment Resources

Why Use Propane-Powered Equipment?

What Is the PHP Process?

Polished Concrete Done Right

Green Umbrella Equipment

Green Umbrella Process

Forty percent faster at startup and 600 percent faster to 5,000 sq. ft.

The Green Umbrella® GreenXtreme™ is designed to tackle any large-scale profile, hone, and polish (PHP) project. Outfitted with three heavy-duty planetary gearboxes driven by hi-flow hydraulic systems common to track-steer equipment, the GreenXtreme is specifically equipped for wet grinding in any environment. It has a standard quick-change system to promote even abrasive wear and quick field changes, cutting downtime on PHP projects.

High-Performance GreenXtreme

Equipment Description:

The Green Umbrella® GreenXtreme™ is the highest-productivity concrete grinder for post-placement surface profiling, coating removal, or polishing. It is outfitted with the industry’s oldest and most reliable mining industry-inspired, durable, self-contained gearbox. GreenXtreme is the solution to any sizeable concrete surface refinement project. The 77” cutting path makes quick work of any surface coating removal, coating prep, profile and seal, or full PHP (profile, hone, polish).

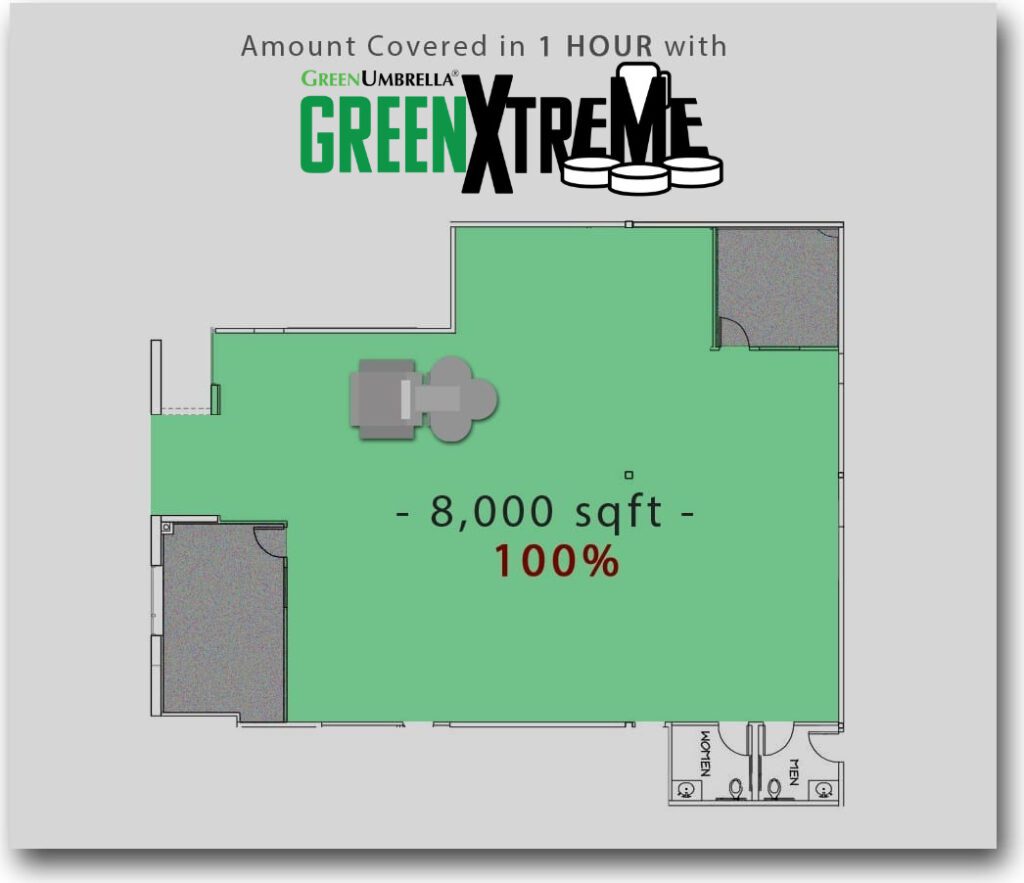

Capable of completing 8,000 sq. ft. per hour, the GreenXtreme is the solution to advancing any construction or production schedule without other equipment downtimes. Powered by specific hi-flow (40 GPM hydraulic flow required), track-steer equipment enables a single operator and a spotter to complete the work of six employees, drastically cutting labor.

RTPMAX gives your crew the highest productivity concrete profiling, honing, and polishing for post-placement concrete in the marketplace today. Our experts can suggest which Power Trowel you will need to accomplish your customer’s goals. Our gearbox can be attached to rental power trowels as well.

Cut Your Labor

- Profile, hone, and polish concrete at an astounding 8,000 sq. ft. per hour using a single operator

Cut Your Downtime

- Diesel-powered engines and propane-powered equipment eliminate the need for electricity to facilitate profiling in any environment and phase of construction

- Fewer employees are needed to get the job done

- Unparalleled productivity

Cut Your Environmental Impact

- Cord-free profiling using water improves indoor air quality during construction and after

- HVAC ducts will be clean and clear

GreenXtreme™

- Production: 8,000 ft2 / 750 m2 per hour-double pass

- Hydraulic: 35-37 GPM / 132-140 LPM

- Drum Speed: 1,980 RPM

- Head Power: 3 x 23 HP / 3 x 17 kW

- Head Speed: 840 rpm counterclockwise

- Head Pressure: 933 pounds / 423 kg

- Grinding Width: 74 inches / 1.9 m

- Vacuum Ports: 3

- Dimensions of Heads: L 192″ x W 77″ x H 80″

- Head Assembly Weight: 2,975 pounds / 1,350 kg

FEATURES & BENEFITS

GreenXtreme™

- Heavy-duty grinder for PHP or coating removal

- Designed to cut wet

- Cordless

- Endless runtime

- Zero indoor air quality issues

- Flex-housing construction for floating cut capabilities

- Uniquely meets LEED maintenance requirements

- Versatile

- No need for two machines for trowel profile, hone, and polish

- Quick change abrasives

- EPA- and CARB-certified

- Simple contractor design

- Easy onsite access for maintenance and repair

- The industry-leading complete system grinder

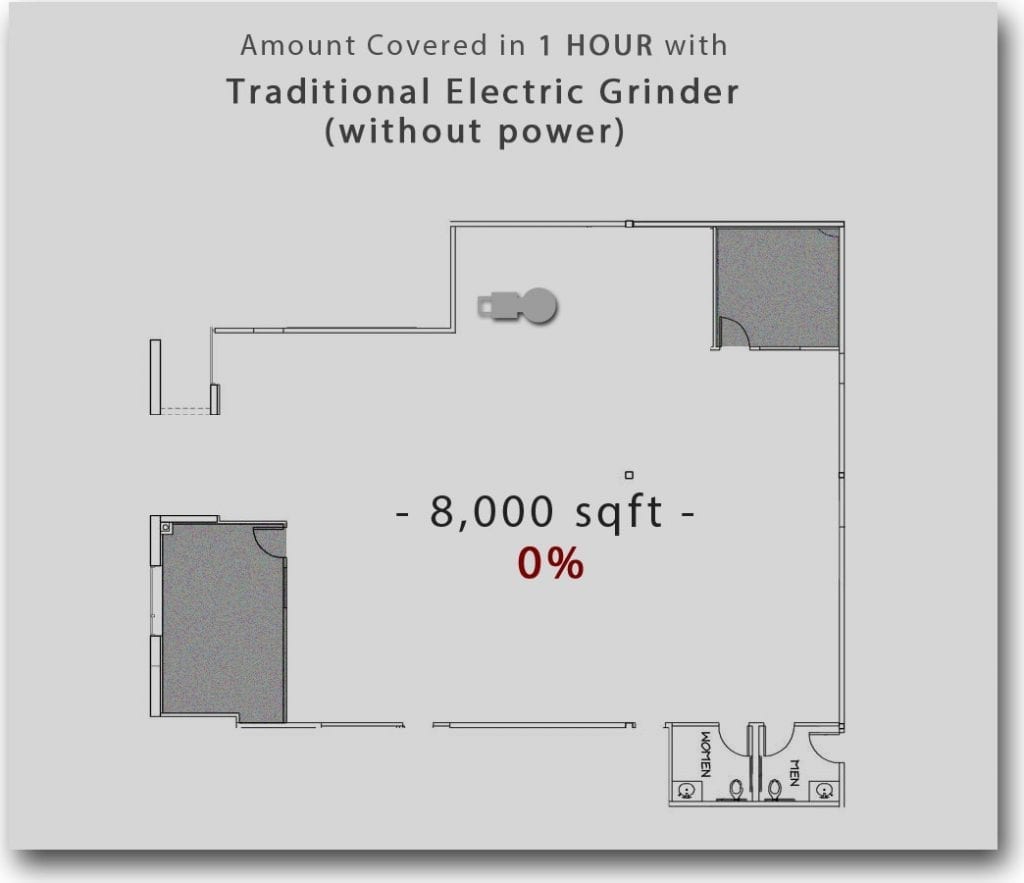

100% Covered in 1 Hour with GreenXtreme™

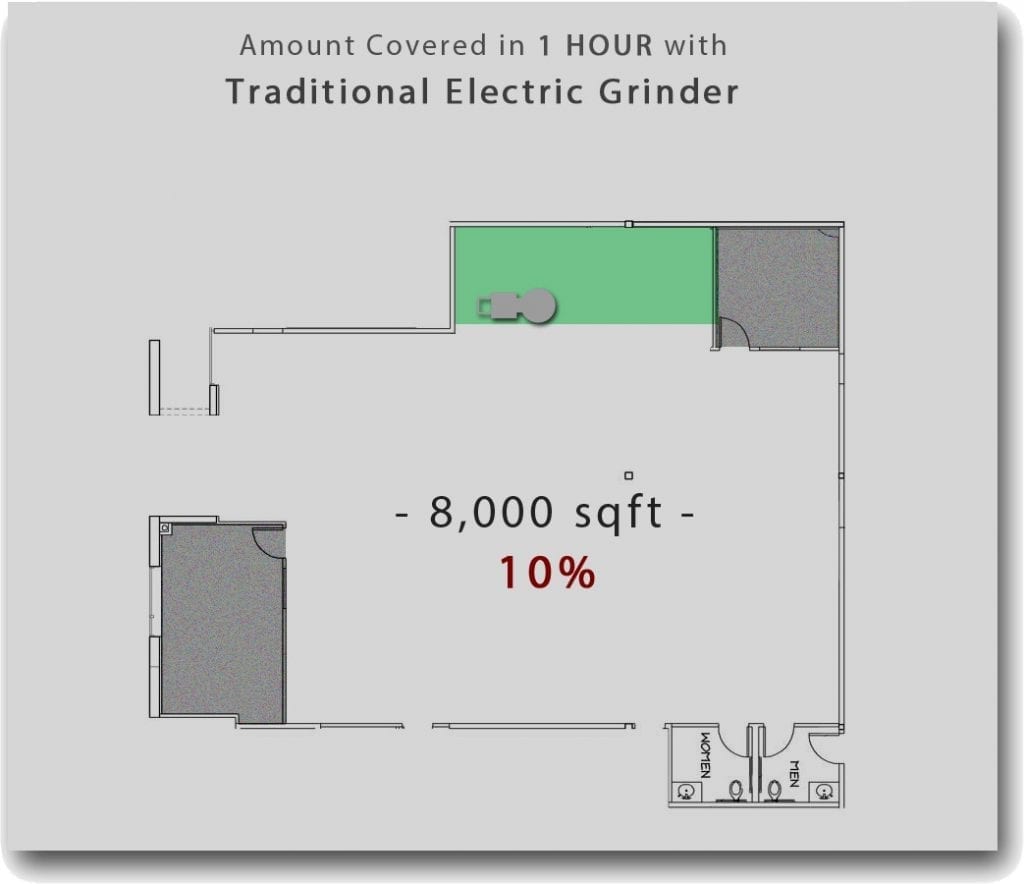

10% Covered in 1 Hour with Traditional Electric Grinder

0% Covered in 1 Hour with Traditional Electric Grinder (without power)

Water + Head Pressure + Cutting Edge = Refinement

Cut the Cord!

Cordless diesel or propane power eliminates the potential hazard of water meeting electricity. Catalytic mufflers ensure minimal impact on indoor air quality from diesel-powered skid-steers.

Reduce the risk of trip and fall accidents. No danger of running over power cables with equipment.

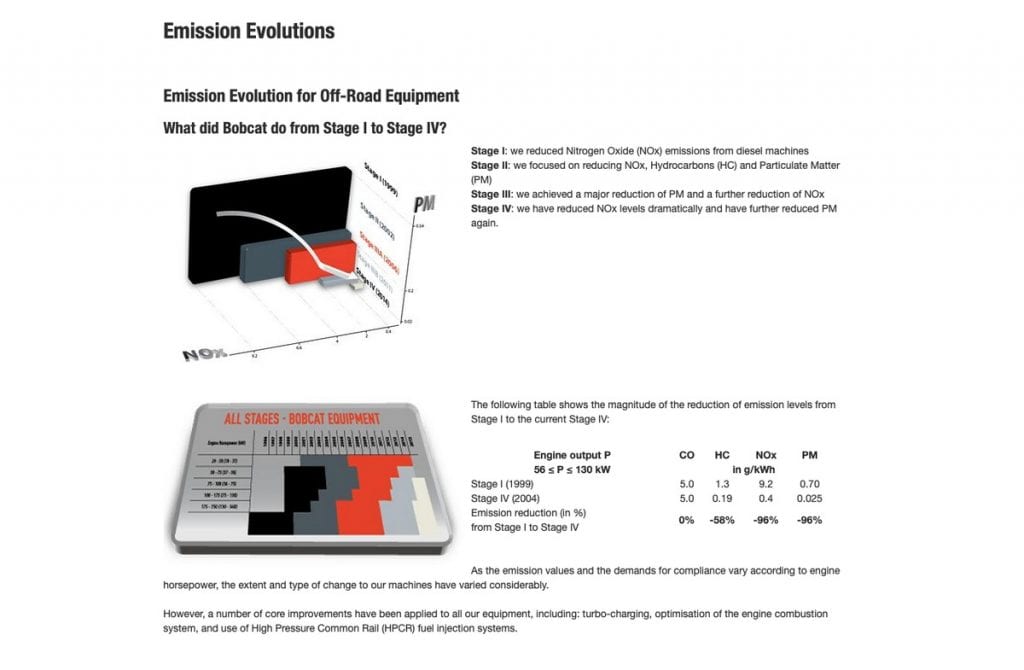

If using a Bobcat as the skid-steer powering the GreenXtreme, emissions are reduced drastically and will continue to be reduced as a part of Bobcat’s commitment to environmental responsibility.

Additional Feature:

The GreenXtreme™ is designed specifically for a wet cut. The wet process uses water to cool abrasives and eliminate dust. Water reduces abrasive friction and acts as a lubricant, thereby increasing the lifecycle of profiling and honing abrasives. The wet process eliminates airborne crystalline silica dust and its potential health hazards, such as silicosis, and improves indoor air quality.

The Hidden Issues

Abrasive Cutting with Electric Equipment: Hurry up and wait! Electric-powered machines generally require 3-phase power wired by a certified electrician and draw considerable power from the facility. Green Umbrella recommends using renewable resources, such as diesel- and propane-powered, clean-burning EPA- and CARB-certified engines.

Hidden Cost to Ownership: Calling the facility maintenance team and requesting an electrician to establish suitable power is just the start. Each electric machine will draw substantial kilowatts of energy during the project.

Sample Electric Grinder Motor (40 Amps – 460 Volts) – 31.8 kilowatts x 0.12 cents per kWh = $3.82 per unit per hour. Average daily operating cost (8-hour day) – $30.53 per machine paid by facility ownership daily.

Sample Project: 5-day project using 2 electric machines will total $305.30 in “hidden cost” to ownership.

Equipment That Is NOT Designed to Cut Wet: While Green Umbrella’s grinders are designed to cut wet, electric grinders are not. Water and electricity do not mix! Eliminate danger and protect workers without introducing harmful silica dust into the air by using equipment designed for the wet profile, hone, and polish process. Propane- or diesel-powered machines eliminate the potential hazard of water meeting electricity.

Expensive Portable Generators and Cords: Not required when using Green Umbrella grinders. Construction sites are filled with potential hazards. Eliminate the potential for a trip and fall accident by eliminating the use of cords while profiling, honing, and polishing. Choose cordless propane or diesel equipment.

Message Us

Get in touch below to learn more about Green Umbrella equipment and abrasives.

CALL US AT (844) 200-7336

OFFICE LOCATION

20 Jetview Drive

Rochester, NY 14624

OPEN HOURS

M-F: 9am – 5pm

info@greenumbrellasystems.com