DryShield

Product Downloads

Specification Downloads

FILLING THE VOIDS

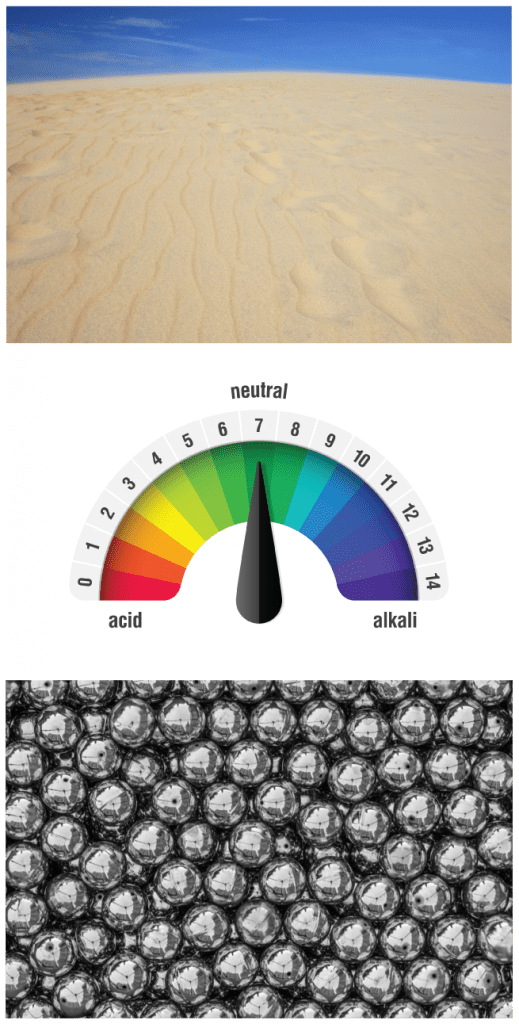

Green Umbrella® DryShield™ is an environmentally-friendly concrete hardener and densifier. Reaching deep within the subsurface, DryShield creates more than a conventional shell surface. The unique formulation is insoluble, fully reactive, and pH neutral—resulting in a bond within the concrete that is harder, denser, and less porous while allowing maximum penetration of concrete colorants. A breathable, transparent, odorless solution specially formulated as a CrossOver™ densifier. Designed for application @EarlyAge™, @Profile&Polish™, or @MatureAge™. Unlike conventional hardeners, DryShield is a single application S.O.L.O™ treatment that requires no scrubbing or mopping. It does not require a pH balance of wastewater if rinsed. DryShield produces a substrate that will stain less and wear longer, reducing maintenance frequency and extending the concrete’s lifecycle.

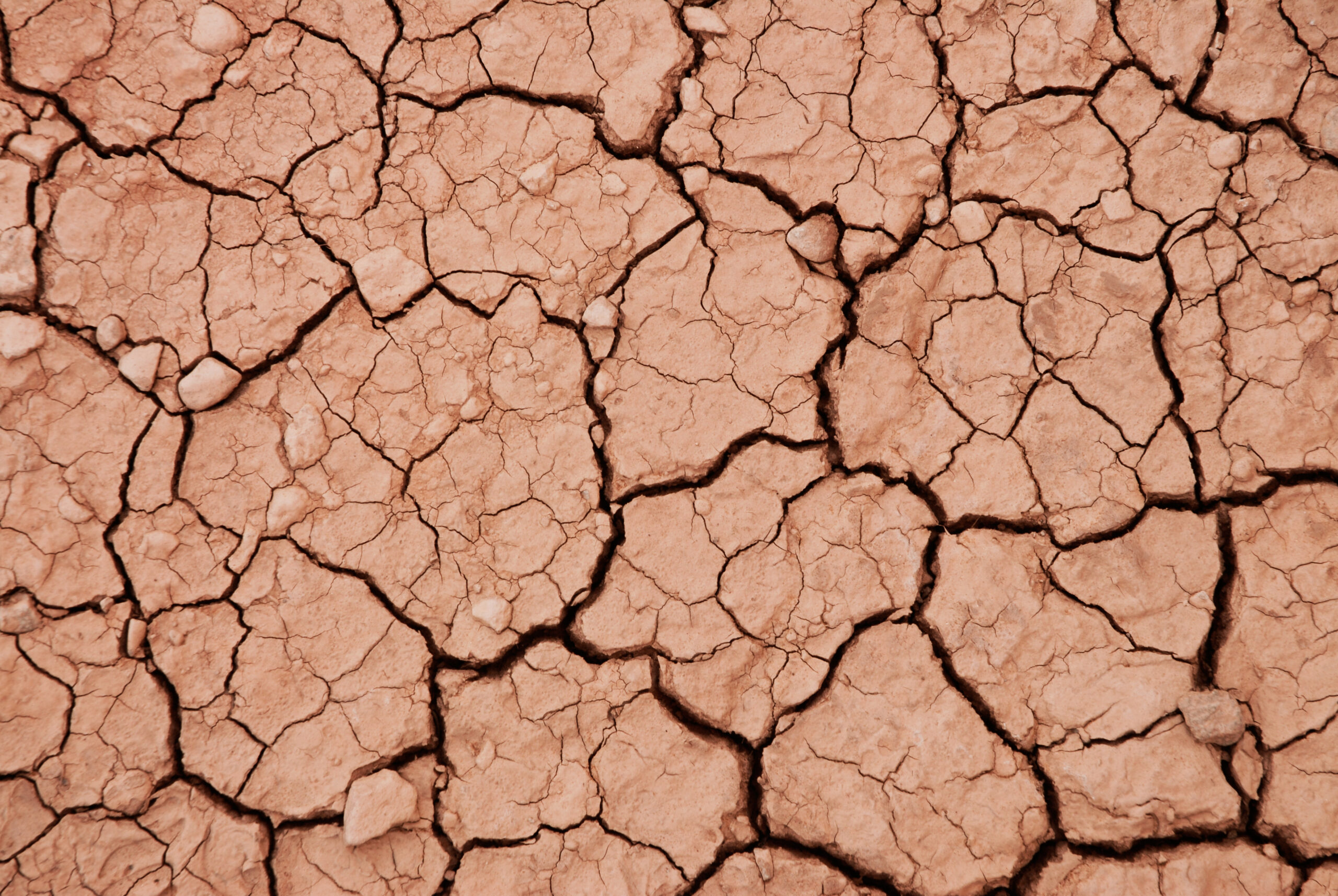

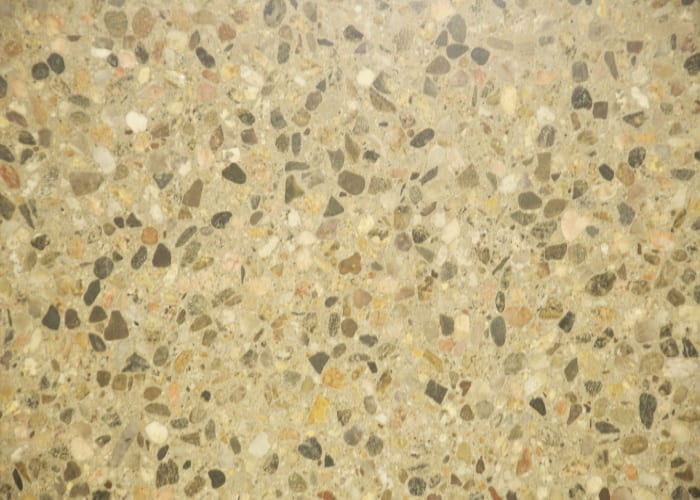

As water evaporates from the riverbed’s surface, the mud slowly shrinks and pulls apart, leaving what looks like valleys and canyons up close. When the rain returns, the water hydrates the cracked and dry dirt, filling the voids. Magnified concrete looks similar. DryShield flows into the concrete’s valleys, canyons, and craters and fills them, becoming part of the concrete and creating a tight surface. DryShield is a penetrating, completely reactive, hydrophilic insoluble nano densifier.

EXPLORE GREEN UMBRELLA ARCHITECTURAL APPLICATIONS

Whether interior or exterior, vertical or horizontal, use Green Umbrella® products in:

• Demanding applications like warehouse and distribution centers, food service facilities, parking decks and garages, hospitals, and similar structures

• Decorative color applications like retail spaces and showrooms, restaurants, business offices, lobby areas, museums, municipalities, airports, hospitals, schools, fire stations, and most concrete surfaces

DEEP SUBSURFACE

PH-NEUTRAL DENSIFIER

HIGHLY-ABRASION RESISTANT

DRYSHIELD’S PRIMARY FEATURE: INSOLUBILITY

DryShield is insoluble. Once DryShield has reacted within the concrete, it will not come out.

Cut Your Labor

- No scrubbing or agitation is required during

application - S.O.L.O.™ application and R.T.U.™ treatment

- Requires no laborious hazardous material disposal

Cut Your Downtime

- 30-minute dwell time and short dry time

- 3 hours to all traffic and abrasive

- No 28-day application restriction

Cut Your Environmental Impact

- Alternative to off-gassing flooring

- Extends lifecycle of concrete

- No VOCs and pH neutral

Features & Benefits

• Industry’s most versatile crossover densifier @EarlyAge™, @MatureAge™, and @Profile&Polish™

• Insoluble and product permanence means it will not wash out

• Superior stand-alone concrete hardener, 2x hardness of conventional hardeners

• Natural silica formulation and environmentally responsible

• Unique nanotechnology offers superior performance

• Deepest subsurface penetration, 10x deeper than conventional hardeners

• Prevents dangerous off-dusting and is safer for building occupants

• Resists penetration by many oils, chemicals, and other stain-causing materials*

• Non-hazardous and pH neutral

• 100 percent reactive, creating more than a shell surface

• 100 percent absorbable, cutting waste

• Low solids formulation and deeper penetration

• Reduces porosity and increases the lifecycle

• Creates a breathable surface without flaking or peeling

• Natural appearance

• Leads to a reduced cleaning schedule

• Requires no rinsing and disposal, cutting labor

• Will not gel on the surface

• No swelling in pores that creates craze cracking

• Simply air dry, cutting labor

• Highly abrasion-resistant to foot and wheeled traffic, increasing lifecycle

• S.O.L.O.™ application and brief dwell time, cutting downtime

• Non-sodium and won’t contribute to alkali-silica reaction

• No efflorescence and whitening common with conventional floor products

• No VOCs and environmentally responsible

• Non-resinous polymer formulation that prevents yellowing and tire marking

• 2-3x greater coverage rate of conventional floor products, cutting labor

*(Low viscosity, high detergent, and chlorinated oils require MaxDefense™)

Additional Features & Benefits for @EarlyAge™ Concrete

• Does not require calcium hydroxide reaction and may apply the same day as pour

• No 7- to 28-day application restriction, meaning less downtime

• Not a desiccant and will not damage cure of surface

Additional Features & Benefits For Abrasively Polished Concrete

• Designed for wet profile, hone, and polish process

• No slab whitening

• Combines with nano colorant and is a one-step color densifier

• Special formulation provides increased concrete colorant retention

• No concrete sweating after application, preventing long downtime for slab recovery

• Deeply subsurface and won’t cut off during profiling, honing, and polishing stages

Standards and Testing

• ASTM C779

• ASTM C1583

• ASTM 1308 with the MaxDefense™ system

• USDA compliant

• FDA approved

Green Umbrella DryShield

1

It may be applied on the day of the pour with no adverse effects.

Conventional Concrete Densifier

28

Wait 28 days after the pour for proper concrete reaction.

Cut Your Product Usage

The product application is formulated for open concrete with 400 to 500 square feet per gallon. With a cutting agent, like GreenCut®, the product requirement usage increases to 600 square feet per gallon. Conventional concrete hardeners are typically applied at 150 to 300 square feet per gallon. DryShield is a S.O.L.O.™ treatment that only requires one application, unlike common hardeners.

If specifying more than DryShield,

make the complex simple

by checking our complete concrete systems.

Message Us

Learn more about how DryShield adds beauty and durability to polished concrete floors.

CALL US AT (844) 200-7336

OFFICE LOCATION

20 Jetview Drive

Rochester, NY 14624

OPEN HOURS

M-F: 9am – 5pm

info@greenumbrellasystems.com