IceStop Fixative

Product Downloads

Specification Downloads

CutSpec: Short Specification

CSI Specification with Designer Notes

Stop the Damage @EarlyAge

Green Umbrella® IceStop™ is applied on the surface as the second part of the Greenlce Cure™ system. Working as a fixative, IceStop is sprayed on concrete once power trowels are finished. It creates a protected slab while curing, extending protection during construction. With specially designed properties, this treatment will densify and add abrasion resistance while repelling water. lceStop increases the strength and longevity of any concrete surface, whether covered or exposed, in an architectural concrete setting. Gloss readings average in the 40s. Start with a high-performance floor and ‘stop’ the damage @EarlyAge™.

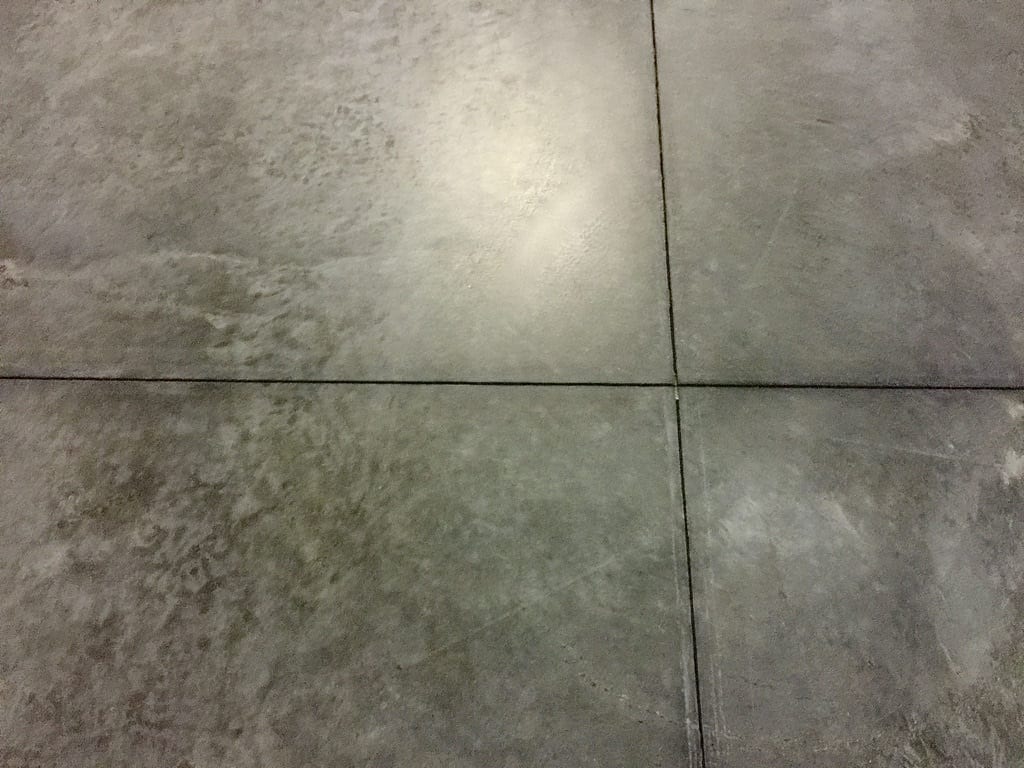

ICESTOP CREATES A DURABLE CONCRETE FLOOR WITH MODERAT GLOSS/SHINE

- Concrete cure

- Advance the construction stage

- Finishing aid

- Eliminate bond issues for flooring

- Minimizes false set

- Minimizes crusting

- Closes capillaries to water and vapor transmission

- No free water, creating denser concrete

- Surface applied admixture

- Neutral pH and calm surface reaction

- Increase ACI 302 window of finish ability

- Mechanical and chemical densification

- Compression dewatering of slab

- GreenIce Cure penetration >25mm (>0.98″)

- Moisture retention evaporation control

- Prevents rapid surface moisture loss

- Passes ASTM C156 and E96 parameters for curing

- Maximum moisture retention for cement hydration

- Extended workability of the slab surface

- Provides the ability to correct errors in finishing

- Reduces drag on trowel blades, decreasing subsurface parallel micro-fracturing

- Significantly reduces surface crazing

- It can be used in conjunction with trap rock or dry shake hardeners to ease their application

- Densify at placement, no return, no remobilization

- Hard troweled surface without over-troweling

- Ease of finishing and eliminates false set

- Reduces drag on the concrete

- Reduces subsurface lateral micro-cracking

- Removes cat faces

- Increases window of finish ability in hot weather

- Does not extend set times in cold weather

- No more chasing a slab that is quick setting

- Best practices provide exceptional finish and strength with superior FL and FF results

IceStop is applied on the surface as the second part of the Greenlce Cure™ system. Working as a fixative, IceStop is sprayed on concrete once power trowels are finished. It creates a protected slab while curing, extending protection during construction. With specially designed properties, this product will densify and add abrasion resistance while repelling water.

lceStop increases the strength and longevity of any concrete surface, covered or exposed, in an architectural concrete setting.

Gloss readings average in the 40s. Start with a high-performance floor and ‘stop’ the damage @EarlyAge.

Cut Your Labor

- Enhances lifecycle, reducing future repairs

- S.O.L.O. application and R.T.U. treatment

- @EarlyAge membrane-forming cure and densifier, reducing construction mobilizations

Cut Your Downtime

- @EarlyAge sealer that provides early protection

- Short dry time

- Three hours to traffic

Cut Your Environmental Impact

- Treatment reduction, a 2-in-1 cure and densifier

- Extends lifecycle of concrete

- Increased abrasion resistance

Cut Your Downtime

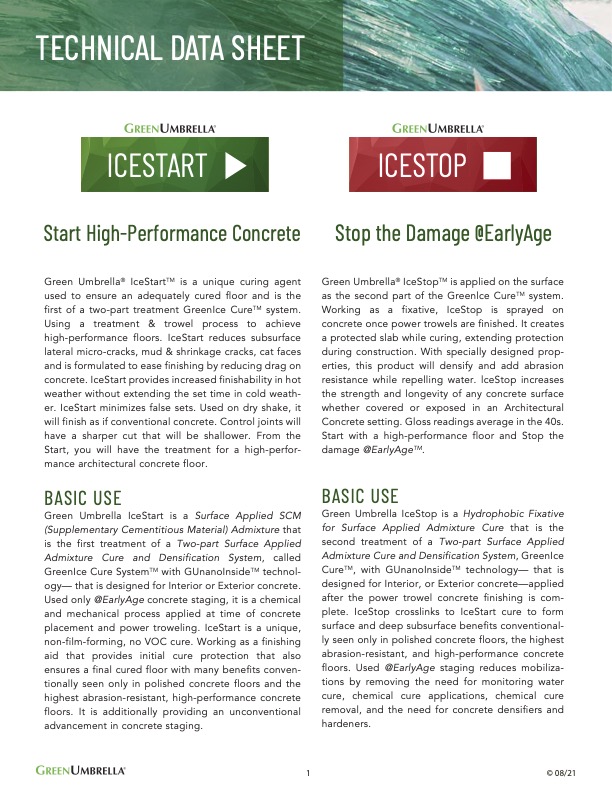

The GreenIce Cure™ system results in a cured, sealed concrete floor with polished concrete properties the same day the slab is poured.

1

GreenIce

7

Water Cure

14

Chemical Cure

28

Densified Floor

49

Conventional Polished Abrasive Concrete

Number of Days spent waiting after the pour and finish.

MESSAGE US

Get in touch and learn more about the GreenIce Cure system for polished concrete floors.

CALL US AT (844) 200-7336

OFFICE LOCATION

20 Jetview Drive

Rochester, NY 14624

OPEN HOURS

M-F: 9am – 5pm

info@greenumbrellasystems.com