ColorPac

Specification Downloads

CutSpec: Short Specification

CSI Specification with Designer Notes

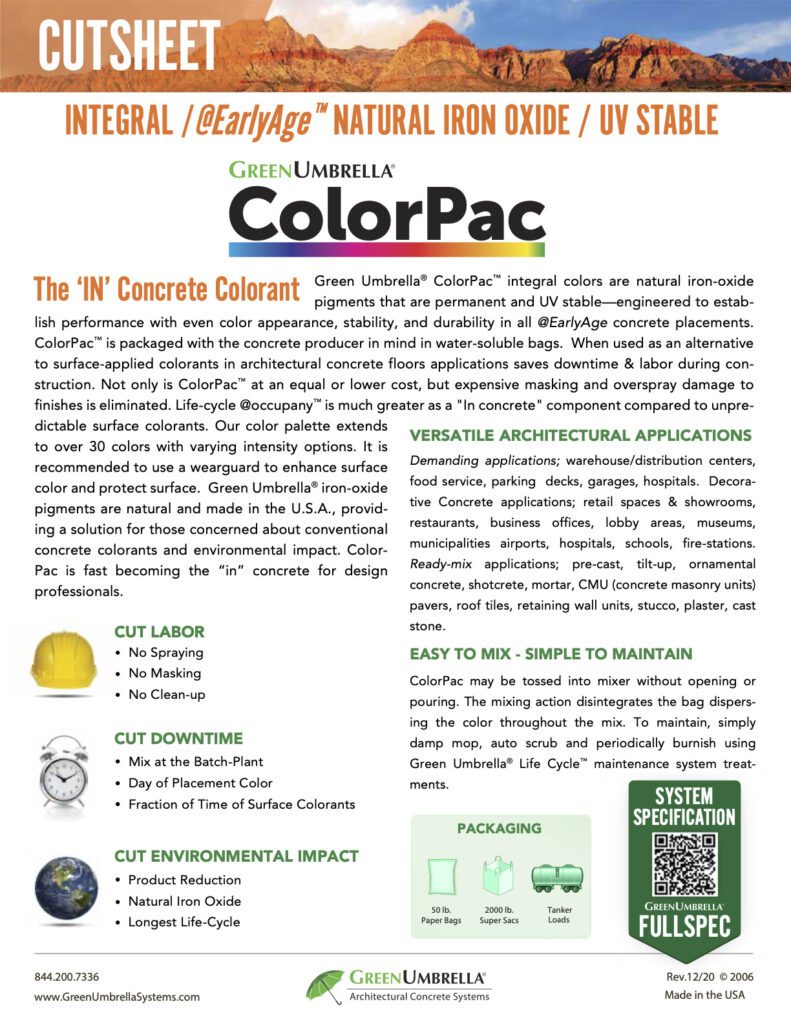

THE ‘IN’ CONCRETE COLORANT

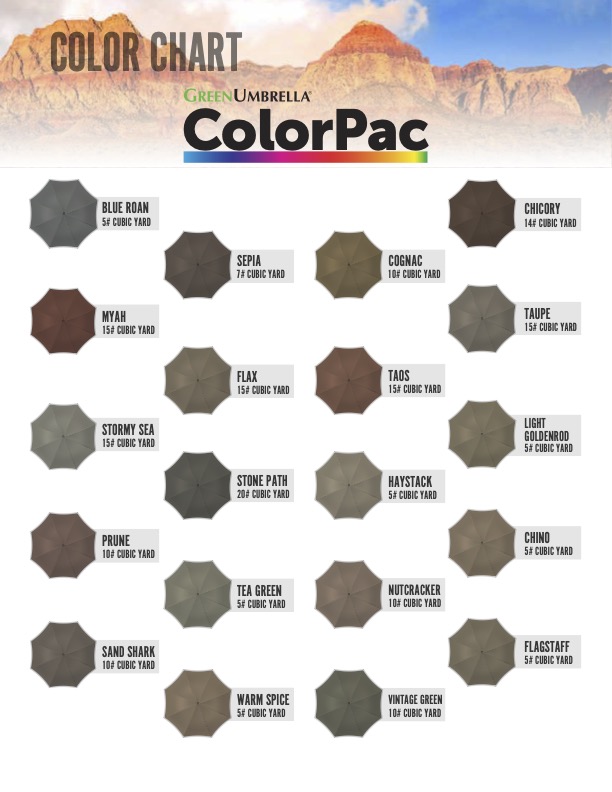

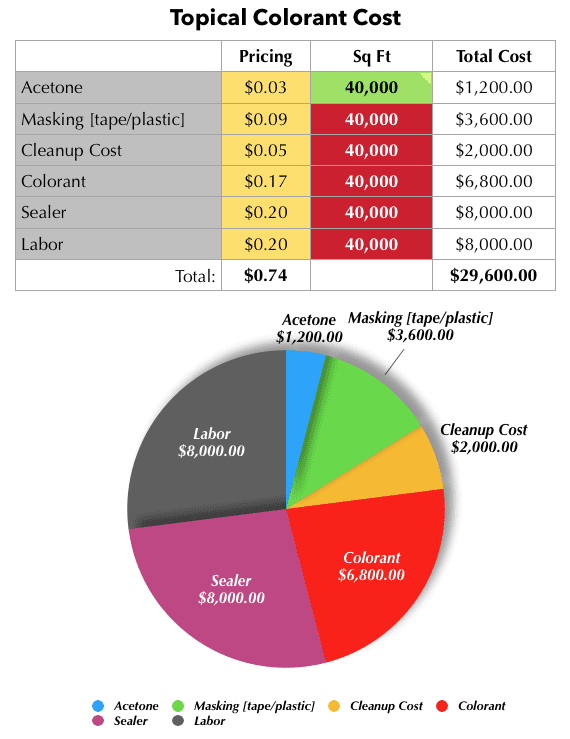

Green Umbrella® ColorPac™ integral colors are natural iron-oxide pigments that are permanent and UV stable—engineered to establish performance with even color appearance, stability, and durability in all @EarlyAge™ concrete placements. ColorPac is packaged with the concrete producer in mind in water-soluble bags. Saves downtime and labor during construction when used as an alternative to surface-applied colorants in architectural concrete floor applications. Not only is ColorPac at an equal or lower cost, but expensive masking and overspray damage to finishes is eliminated. Lifecycle @Occupancy™ is a superior ‘in’ concrete component compared to unpredictable surface colorants. Our color palette extends to over 30 colors with varying intensity options. It is recommended to use a wear-guard to enhance the color and protect the surface. Green Umbrella iron-oxide pigments are natural and made in the U.S.A., providing a solution for those concerned about conventional concrete colorants and environmental impact. ColorPac is fast becoming the ‘in’ concrete for design professionals.

THE NEXT GENERATION OF CONCRETE COLORANTS

Green Umbrella & ColorPac

Green Umbrella® ColorPac™ integral colors are natural iron-oxide pigments that are permanent and UV stable—engineered to establish performance with even color appearance, stability, and durability @EarlyAge™ concrete placements. Use as an alternative to topically applied color and reduce downtime and labor. Lifecycle @Occupancy™ is much greater being an “in” the concrete component compared to unpredictable near-surface colorants. Our color palette extends to over 30 colors with varying intensity options. Green Umbrella iron-oxide pigments are natural and made in the U.S.A., providing a solution for those concerned about conventional concrete colorants’ environmental impact.

extends over 30 colors with additional intensity options. Green Umbrella iron-oxide pigments are natural and made in the U.S.A., providing a solution for those concerned about conventional concrete colorants’ environmental impact.

CUT YOUR LABOR

- No separate equipment or crew needed to introduce color into architectural concrete

- Color is introduced at the batch plant

CUT YOUR DOWNTIME

- ColorPac is added quickly and easily during batching

- No need to block off areas waiting for surface treatments to dry

CUT YOUR ENVIRONMENTAL IMPACT

- No harmful acids, solvents, or chemicals

VERSATILE ARCHITECTURAL APPLICATIONS

ColorPac™ is a Green Umbrella® concrete colorant that meets the versatile product demands of architectural concrete design professionals for exterior and interior concrete. It uses pigmented iron oxide. Use it in applications where concrete dyes or stains are usually specified and where high-performance, sustainability, UV stability, and ROI are of concern.

FEATURES & BENEFITS

- An insoluble product that won’t wash out

- Applied same day as pour

- Natural appearance

- Requires no rinsing or disposal

- No VOCs

- Won’t cut off during profile, hone, or polish

- Use with polished and non-polished concrete

ColorPac is formulated for use in these settings:

- Industrial

- Manufacturing

- Light assembly

- Warehouse/distribution centers

- Food service operations

- Retail stores and showrooms

- Parking decks

- Garages

- Airports

- Hospitals

Cost Comparison: Topical vs. Integral Color

40,000 square feet

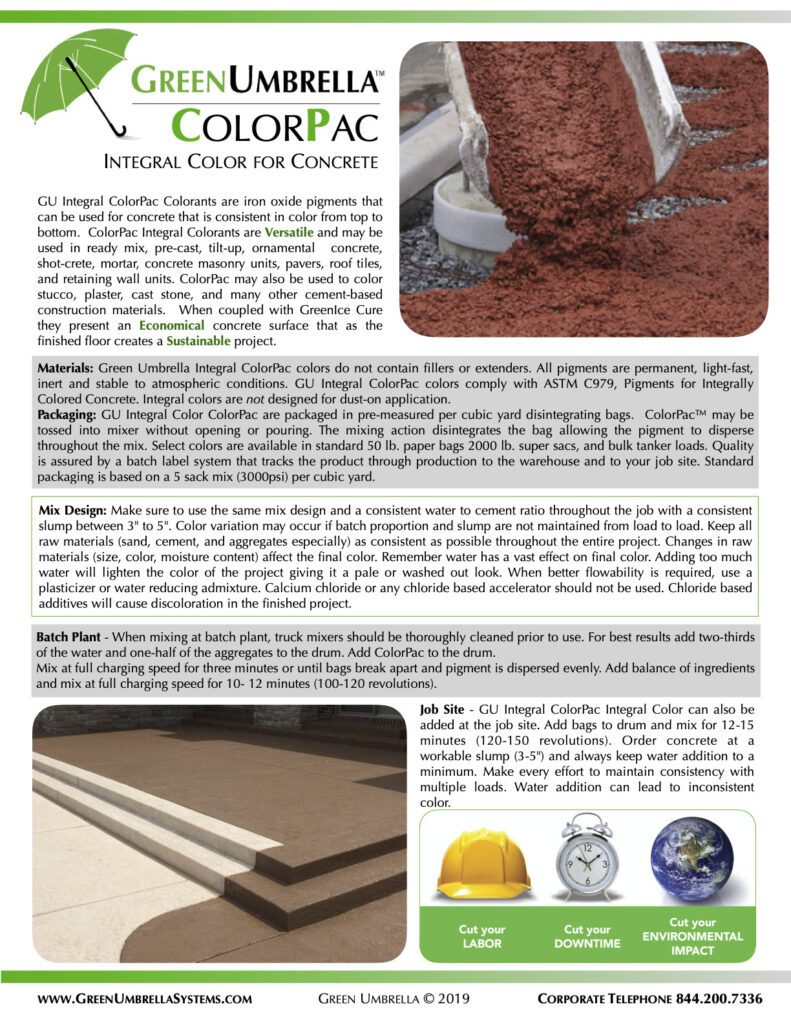

Materials: Green Umbrella® ColorPac™ colors do not contain fillers or extenders. All pigments are permanent, lightfast, inert, and stable to atmospheric conditions. ColorPac colors comply with ASTM C979, Standard Specification for Pigments for Integrally Colored Concrete. Integral colors are not designed for dust-on applications.

Packaging: Green Umbrella® ColorPac™ is packaged in pre-measured disintegrating bags. It may be tossed into the mixer without opening or pouring. The mixing action disintegrates the bag, allowing the pigment to disperse throughout the mix. Select colors are available in standard 50 lb. paper bags, 2,000 lb. super sacks, and bulk tanker loads. A batch label system ensures quality by tracking the product through production to the warehouse and your job site. Standard packaging is based on a 5-sack mix (3,000 psi) per cubic yard.

If specifying more than ColorPac, make the complex simple

by checking out Green Umbrella concrete systems.

MESSAGE US

Get in touch to find out what Base Defense can do for your next concrete project.

CALL US AT (844) 200-7336

OFFICE LOCATION

20 Jetview Drive

Rochester, NY 14624

OPEN HOURS

M-F: 9am – 5pm

info@greenumbrellasystems.com