GreenCut

Request a product specification for your next project.

The Foundation of the Profiled Floor

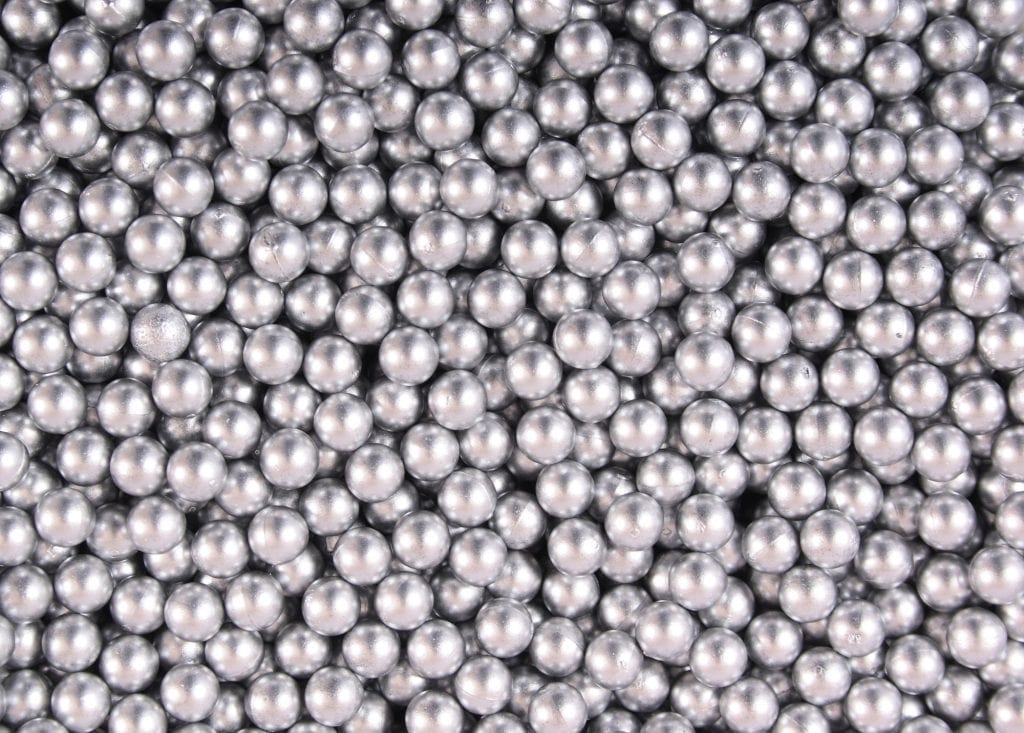

Green Umbrella® GreenCut® is a neutral, nano-surface profiling agent that teams with slurry produced during wet profiling. The rounded nano-structure surface refinement treatment advances abrasive profiling. As part of the GreenCut Abrasive Profile™ system, silica-based nano-marbles mill and fill the substrate during profiling, removing and rolling stock beneath abrasive tooling. This cutting action removes high spots using the edge of the abrasive in a way never before achieved, acting as a lapping compound. GreenCut impacts the surface, reducing the average seven-abrasive process to two or three. GreenCut should be used on every abrasively profiled project—cutting labor, downtime, and environmental impact. Green Umbrella’s liquid cutting agent produces polished concrete that cannot be replicated in quality, durability, or quantifiable RA. GreenCut is free of harmful acids, damaging formulations, polymer-based solids, and surfactants. Produce superior floor value, increasing concrete substrate quality with an ultra-fine surface refinement not possible using equipment and abrasive tooling alone. GreenCut produces a microscope-worthy profile with a smoothness that can be felt by touch after the first cut.

The Foundation of the Profile, Hone, and Polish Process

GreenCut® should be used on every PHP (profile, hone, polish) project. It attacks the concrete using microscopic cutting beads to generate a surface primed for honing and polishing. Put simply, GreenCut® will give you a superior final product with less time, labor, and environmental impact.

GreenCut® is a registered trademark of Green Umbrella and has been in the public domain since 2010.

Hydrate

1. Hydrate the concrete substrate using water.

GreenCut® is part of a wet process that prevents dust from contaminating the air and HVAC system, thereby removing indoor air quality concerns.

Saturate

2. Saturate the surface using GreenCut®.

Introduce GreenCut® onto the concrete surface evenly (broom if necessary for even disbursement) and allow time for the treatment to penetrate the surface.

Profile

3. Profile

Using a profiling abrasive tool in conjunction with the liquid abrasive GreenCut® leads to a superior profile during the honing and polishing stages of concrete refinement.

REDUCE BONDED ABRASIVE USAGE

Green Umbrella® GreenCut®

GreenCut® starts by preparing the concrete, leading to faster and more efficient profiling and processing. The frothy slurry created by the process is deposited back into the floor to help seal pores, producing a denser surface.

GreenCut® helps create a more resilient floor with a superior gloss while saving time and money and eliminating hazardous waste disposal issues—significantly reducing your company’s environmental impact.

GreenCut® is specially formulated for wet PHP (profile, hone, polish) systems. It should not be used with all abrasive tooling. Test the abrasive before attempting to complete large areas.

Cut Your Labor

- GreenCut® reduces labor requirements and significantly reduces wear on your metal bond abrasives

Cut Your Downtime

- GreenCut® allows for using as few as two abrasive steps to profile, hone, and polish concrete floors

Cut Your Environmental Impact

- GreenCut® is part of a wet cut process that eliminates airborne contaminants and reduces the number of materials used

Features & Benefits

- Reduces the number of abrasive grinding steps

- Cutting and slurry agent

- Creates a less porous surface

- Improved productivity

- Metal bond abrasives last significantly longer

- Super high gloss if desired

- Can be colored using a dye or micro-pigment

GreenCut® in Action

Cut Your Downtime

9

The conventional profile, hone, and polish process requires 5 to 9 abrasive tools, making an unknown number of passes to complete a basic polished concrete floor.

4

GreenCut® nano-cutting agents allow unrivaled concrete profile, hone, and polish using just 3 to 4 abrasive tools, reducing the time and tooling required and increasing gloss, abrasion, durability, and lifecycle of the polished concrete surface.

Request a Project Spec Today!

GET A QUOTE IN UNDER 24 HOURS

CALL US AT (844) 200-7336

OFFICE LOCATION

20 Jetview Drive

Rochester, NY 14624

OPEN HOURS

M-F: 9am – 5pm

info@greenumbrellasystems.com